Authorized Reseller

Authorized Reseller

Stanley S422 Kitchen & Bath Tub & Tile Silicone Sealant (Acetoxy cure) - White/Clear, 10.1 fl oz

(Applied at Checkout)

Stanley S422 Silicone Sealant is a high-performance, acetoxy cure clear waterproof sealant designed for gap filling and sealing in a wide range of sanitary applications. This 100% silicone sealant prevents mold formation on its surface, ensuring a bright and clean finish due to its outstanding mildew and fungus resistance. It offers excellent resistance to direct sunlight, rain, snow, and ozone, making it perfect for both indoor and outdoor use. Ideal for sealant sink and tub sealer applications, it provides a fast drying silicone solution for various needs.

Features & Benefits:

- 100% Silicone: Solvent-free formulation.

- Mold-Proof: Prevents mold formation and stays bright and clean.

- High Elasticity: Low modulus, high elasticity.

- Weather Resistant: Excellent resistance to direct sunlight, rain, snow, and ozone.

- Primerless Adhesion: Adheres to numerous porous and non-porous substrates without a primer.

- Temperature Resistant: Withstands temperatures from -58°F to +392°F.

- Durable: Does not crack or discolor and withstands detergents, cleaning agents, and chemicals.

- Fast Curing: Quick curing process without shrinkage.

- VOC Compliant: Exceeds the requirements of VOC content specifications in LEED credit EQc4.1. Low-emitting products of SCAQMD rule 1168.

Application Areas:

- Kitchens and Bathrooms: Ideal for sealing applications in kitchens and bathrooms with bath and kitchen silicone.

- Connection Joints: Perfect for sealing connection joints.

- Weather Sealing: Suitable for weather seal applications.

- Glazing Works: Effective for glazing applications.

- Sink Sealant: Excellent as a sealant sink.

- Tub Sealer: Can be used effectively around tubs.

- Shower Sealant: Perfect for sealing showers, providing a reliable waterproof sealant for showers.

- Bathroom Silicone: Ideal for use as a silicone for bathroom and sealants for bathrooms.

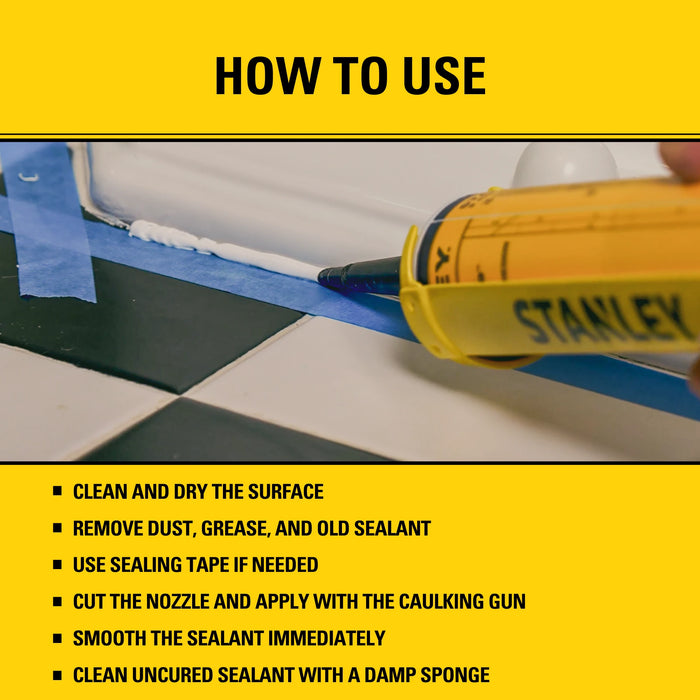

How to Use:

- Safety Precautions: Ensure good ventilation at the work station. Wear personal protective equipment. Do not eat, drink, or smoke when using this product. Always wash hands after handling.

- Surface Preparation: Ensure substrates are clean, dry, and free from dust, grease, rust, and contaminants. Clean non-porous surfaces (like aluminum and glass) with solvent and dry thoroughly. Mechanically clean porous substrates (like concrete and brickwork) with compressed air, sandpaper, or a hard brush. Mask off joint edges with self-adhesive tape for protection.

- Application: Use polyethylene bond breaker tape or backer rod to adjust joint depth and avoid three-sided adhesion. Cut the nozzle to the desired bead size. Apply the silicone sealant as evenly as possible using a professional caulking gun. Tool the joint surface with a smoothing tool to ensure full contact with the sides and backup material before skin formation.

- Finishing: Remove masking tapes immediately after smoothing the silicone seal. Allow the sealant to cure fully.

- Cleaning: Uncured product can be easily removed with a damp sponge. Cured product must be removed mechanically.

Specs:

Basis: Silicone Polymer

Curing Mechanism: Acetoxy Cure

Skin Formation Time: 7-13 min at 73°F and 50% R.H.

Application Temperature: +41°F to +104°F

Packaging: 10.1 fl oz

Shelf Life: 18 months

Storage: Store in a cool, dry environment between +41°F and +77°F.